Frank (short for Frankenstein, because it was built out of reject parts from failed experiments) is an example of design philosophy come full circle. The first prototype CLA-2A was built using carbon comp resistors and nothing special capacitors and didn't sound particularly good, but I did use it on some interesting records. After building 32 or 33 "production" CLA-2As using PC boards, regulated DC supplies, metal film resistors and WIMA MKP-4 and Panasonic electrolytic caps throughout I wanted to build a unit using point-to-point wiring for comparison. I built Frank partly because I knew if I completed it I would never sell it. It was probably the only way I'd get to keep one of my own compressors in my studio :-)

You'll notice some extra controls on Frank's front panel. The two knobs to the left of the Gain pot are to trim each of the gain reduction elements individually. This way, I could get closer to the precise amount of gain reduction I wanted in any particular situation. Also, the Compress/Limit switch is a 3-position, center off toggle switch instead of the usual 2-position. This switch gives 3 possible release curves instead of the usual 1 (on a "real" LA-2A this switch does nothing useful.) The extra knob to the left of the Meter switch is the meter zero pot. I decided to make this a proper control since I fiddled with it so much. That was a great decision and from now on, meter-zero pots will be given the full attention they deserve, including a real pot, knob and a well-deserved spot on the front panel.

Frank is built like a tank - literally. The side panels are solid 1/2" thick steel plate and the front panel is solid 1/4" thick steel plate. This 2U unit weighs 24 pounds (!) making lifting it in and out of the rack a real effort. The front and sides were CNC milled and drilled. The top was cut on a plasma cutter and then trimmed and bent to spec. The black grille on the top cover came from a Teac A-4010S reel-to-reel I gutted for parts. The bottom was an old Ango (nka Par-Metal) panel left over from a batch they flubbed (one of many wrong orders they sent me over the 3 years or so I dealt with them.) The whole enclosure has a 5-layer paint job using an acid-etch layer, then primer and 3 layers of industrial paint. The "VU" meter in these pictures is actually the Modutec unit that is the dimensional equivalent of a Sifam AL-39WF but with a 0-1 ma movement. Shortly after I took these pictures I replaced that meter with a Sifam AL-39WF. I had designed an active meter driver for the Modutec but it was too much hassle to implement so I took the lazy way out and installed a Sifam.

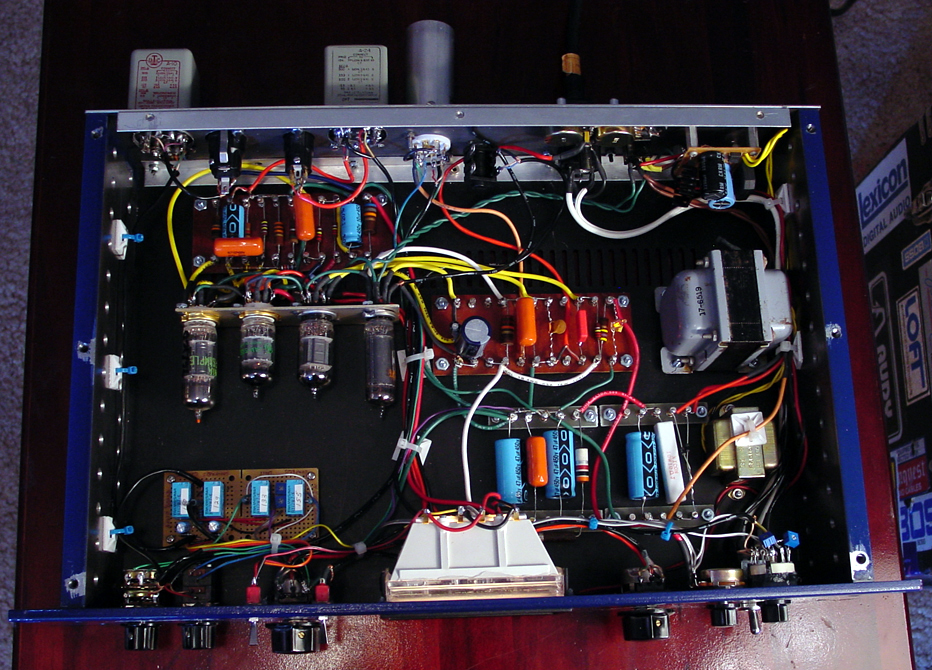

Inside, all wiring was done point-to-point with components laid out on turret boards. Frank was built to test several things. First, to prove to myself that the circuit board layout I designed for the CLA-2A really did deliver an improved signal-to-noise ratio over a point-to-point design. (It did.) Second, to prove that metal film resistors really did sound better than carbon composition types. (They do.) Third, to see if there was any difference in the noise floor when using a regulated DC power supply for the filaments instead of a straight AC supply. (The DC supply is about 2 dB quiter, in this unit anyway.) Fourth, to try out my circuit for providing 3 different release curves instead of the single release curve provided by the stock circuit. I also added pots in series with the photocell pairs to trim the amount of gain reduction provided. The circuit I tried uses relays to switch two different pairs of photocells in and out of the circuit, so three different responses are possible by selecting either pair individually or both pairs in parallel. I also built a custom T4B unit that housed both an EL panel/photocell pair and a pair of Clairex CLM4000's, which are similar to the Vactrol VTL5C1 series of devices. The result was that this unit can deliver authentic LA-2A-style compression or an LA-4-like compression but with a tube gain-makeup amp, or a very aggressive compression similar to a Joe Meek unit. I'm still playing with the design.

The rear panel was photo-etched by a friend of mine and is 20 gauge aluminum. He did a sample run of panels for me but the results were not good enough quality for production CLA-2As. The two pots under the Voltage Select label are actually to calibrate the meter for different photocells, so I didn't have to open the unit up when I tried a different T4B. The toggle switch to the right of the Caution statement switches between regulated DC and unregulated AC filament supplies. The round can next to the output transformer is the custom T4B I built. This unit has a UTC A-10 input transformer and a UTC A-24 output transformer. If you look closely under the transformers you can see labeling for and unbalanced input and output. I originally put unbalanced inputs and outputs on the production CLA-2As but they were a lot of work to wire and nobody ever used them for anything so I stopped doing that. I think it's kind of ironic that the balancing transformers got put there instead. It also uses an OEM Triad R4A power transformer that I bought off Ebay and paid a lot of money for, before I found out about the Hammond equivalent sold by Allied Electronics. Since then I've used the Hammond transformer and found it to be virtually identical for all practical purposes.

This unit also uses a 5751 instead of 12AX7 for the first audio gain stage. Even though 5751s are underbiased in this circuit and therefore burn out after about a year of use they sound great. I'll take great sound over a longer life span any day!